Update to the LDC1000 experiments

A few days after my article about the LDC1000 experiments I got some feedback from TI. They did let me know that

the chip can be used to design a general purpose metal detector. In this application, the coil design would need to change: increasing the coil size or adding a ferrite backing to the coil will increase the detection range.

My initial statement came from what TI touted as usage for the LDC1000 (short-range, high-resolution positioning). Together with the fact that the online WEBENCH tools for the LDC1000 allows design only for sensing to at most 7cm range it seemed that larger distances were not the domain the LDC1000 is intended for. But it seems that this is just a preference, and it actually can be used for longer-range measurements.

Range increase needed

So can we increase the detection range with these hints? Originally I did not set out to build a general metal detector - using the LDC1000 to find some small SMD parts on the floor was purely accidental. To answer this question I first started my testing what the detection range of the unmodified LDC1000 EVM kit is.

When I configured it to the best sensitivity, with a narrow range for Rp, the detection for a 1206 capacitor was reliable up to about 10mm (with a slow sweep of the coil).

Looking for a better coil

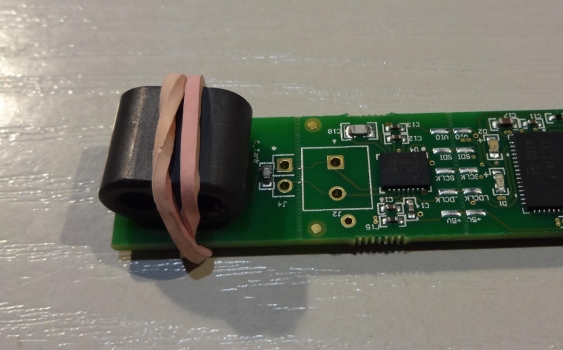

Unfortunately I had no coils with embedded ferrite core available (just some power coils for SMPSs which I think won’t be appropriate for this purpose). I also didn’t want to remove the PCB coil from the EVM right now (it works fine as it is…). So I settled for the simplest alternate solution: add a ferrite core to the PCB coil:

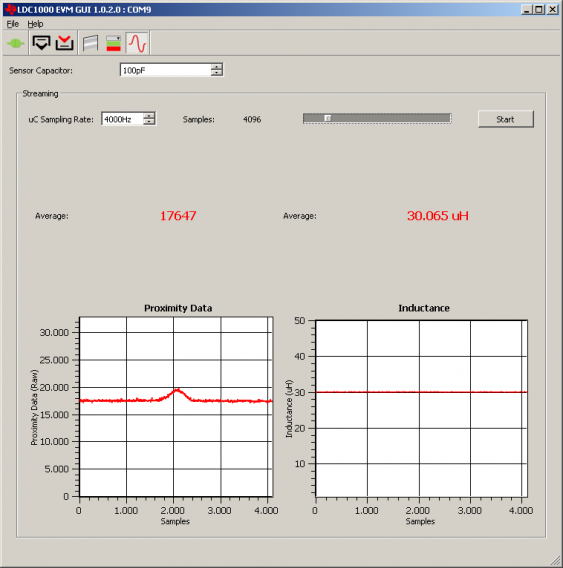

It doesn’t look nice, and is for sure a pretty sub-optimal way for tuning the coil. But does it work? Yes it does, even though its not that much. The needed configuration changes since the inductance of the coil is now different. But the detection range extends now to about 15mm, and inside if this range the detection is more visible:

Outside of the measurement range the detection is basically not visible, and this drop was not as sharp without the ferrite core.

More tests needed

So I guess I should really try with a different coil. So probably I will need to try different coils, lets say from about 5 up to 15cm, and see what I can get out them. Maybe I will also try to make coil with a ferrite core - the one above maybe, or one from an old MW radio (this might give an even more directional response too).

I can also only encourage to look at the WEBENCH tool. It not only allows to calculate basic PCB coil parameters, but also calculates detailed characteristics for it. Inn the end even creates board files for some popular PCB tools (including CadSoft Eagle, but KiCad is unfortunately missing…).

Btw: one nice usage which came to my mind when looking at the LDC1000 show case videos is to detect warping and deforming in machines. Take, for example, a low cost 3D printer. Reportedly it sometimes happens that its rails guiding the print head warp due to errors during erection, or long use. Since the LDC1000 can detect changes in the micrometer range, it could be used to detect such problems. Now I just need a 3D printer to test this… (And since the TI challenge mentioned last time is for US residents (and Canadians) only, I cannot send it in to win something :(