« Wireless power contest - outlining the basic plan

| Main |Wireless power contest - strategies for charging a battery pack, part 2 »

Wireless power contest - strategies for charging a battery pack, part1

When deciding for my basic plan to use a LiIon battery pack, I already knew that charging a LiIon battery pack will probably be the biggest challenge right now. So now it gets time for looking deeper into the issues of that problem.

Why is charging a battery pack difficult

Most devices using LiIon batteries only use a single cell (most prominent are mobile phones). But devices like laptops, that need more power, use a pack of multiple batteries. Typically they come in different arrangements of how they are wired (in series or in parallel), depending on the needed voltage and power. But they all share the same problem: the different batteries inside of the pack are not exactly equal, so they probably all have a different discharge (or charge) state. Why is that problematic?

LiIon batteries are very sensitive to over-charging. They get charged at first with a constant current. Typically this is the 1C current, which is the current that would discharge the battery in 1 hour (so a 2 Ah battery has a 1C current of 1 A). When the battery reaches its final voltage (which is 4.2 V for the most types of LiIon batteries) it then gets charged with a constant voltage (also 4.2 V) until the charge current has dropped to 1/10th of its original value. Charging the battery with a higher voltage, or too long with the constant voltage will permanently damage the battery (or even risk a fire).

Now if we have a battery pack consisting of two cells, we would need to charge it to 8.4 V. But if one of the batteries has been discharged a little bit deeper (which is very likely), it has a lower voltage and will reach its 4.2 V final voltage later. In turn that means that the other cell reaches its final voltage earlier, and since we charge up to the combined voltage of 8.4 V, the better cell will get charged to a voltage higher than the 4.2 V. In turn, the worse cell will not get charged up fully when reaching the constant voltage mode. So cycling several times through this increases the difference between the cells until one of them will get damaged.

Remedies

So basically there are three ways out of this misery - hoping for the best, single-charging and balancing.

The first one is to select cells that are as equal as possible. This can normally only be done by the battery manufacturer as they know best how to measure and characterize the individual cells. Doing that can prolong the problem of inequality long enough to make this a usable option. But with more than two, maybe three, cells makes this much more difficult. These battery packs also get really expensive, so its not really an option for this project.

The second option is to come up with a circuit that is able to charge the single cells individually. That means connecting the charger to a single battery only.

Single cell charging

Again, there are multiple ways to achieve our goal with this strategy. Both have in common that they need a switch to connect / disconnect the battery from the battery pack. The easiest way to do that is to use relays.

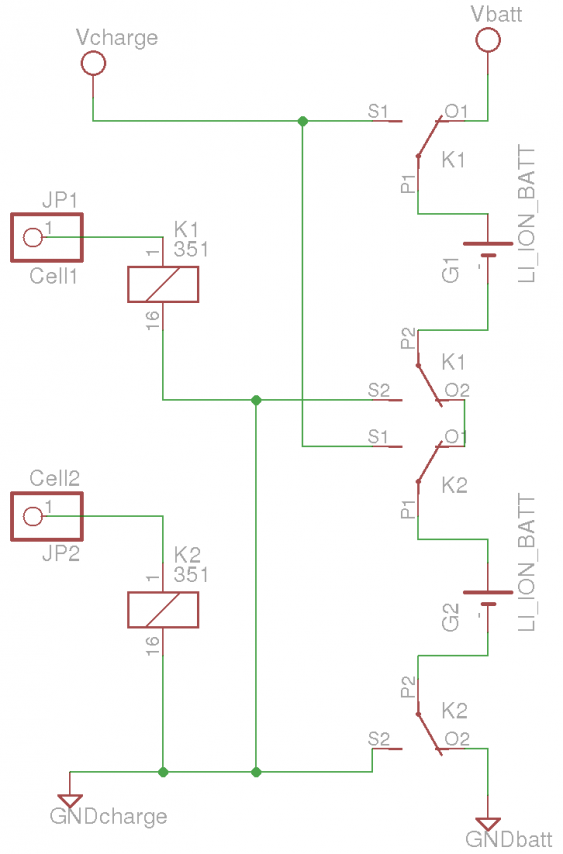

So the first solution is to use the relays to connect one cell only to the battery charger. When that cell is charged, in can be disconnected, and the next cell can be connected to the charger. As schematic, it could look like this:

Both relays are relative to (charger) ground. Normally, the batteries are connected in series and to the output. When one of the relays is activated, it disconnects its corresponding cell from the battery pack (and the output), and connects it to the charger (to both the charging voltage and charging ground). Its not recommended to activate both relays, as then both cells are in parallel, and this leads to potentially high currents between them.

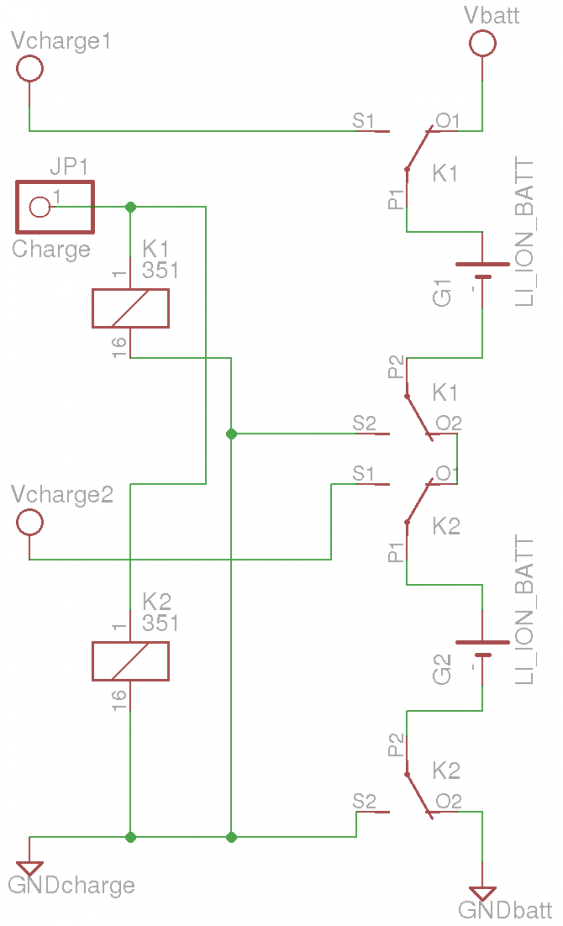

If charging the batteries one after another takes too long, one could use multiple chargers in parallel:

The circuit is somewhat similar to the first one, and the normal connections are the same. But when both relays are activated (they are in parallel), both cells get disconnected, and then get connected to their respective charging voltage (with the other end to the common charging ground).

There is a third option here: one could use ‘floating’ chargers. That means using multiple chargers, as in the last example. But they are not allowed to have a common ground, so each needs to have its own transformer. When this is ensured, the chargers could be connected directly (and permanently) to the cells. Think of it as if each cell had its own power (e.g. Mini-USB) connector, where the respective wall-wart power supply (with a transformer in it) is connected to. But this really needs too much circuitry, and so is no option at all (especially not for this project, since there is no mains power available).

So what about the other solutions? Especially the second one looks promising: LiIon chargers can be very simple. E.g. a LTC4054-4.2 comes in SOT23 package, and doesn’t need so many external components.

But there is the need to use some relays. We would need one relays, in DPDT configuration, to do all the switching. (OK, connecting the grounds together saves us one DPST contact, but still…). And relays take space, and they especially need current. For 5V, there are low power relays available that need just 10 mA. Since I need three of them, thats 30 mA - which is more than 10% of the power budget I was planning with (I was thinking of a charge current of 100 mA per cell). And whats even worse: they are specified for a maximum contact current of 2 A. Since the motors take 2.5 A (maybe even up to 3 A) peak current, I will most likely damage them. All relays I could find that switch higher currents are either too large for my space constraints, or need a current of 50 mA per relay (sometimes even up to 100 mA).

So even though I would come back to that idea for later projects (with lower current needs) I cannot really use it for this one.

Outlook

So for the next article I need to take a deeper look at how multiple cells can be charged while still being in series. I promise there will be a nice solution for that!